Tobacco Shipping and Commerce

As early as 1617, large volumes of tobacco began to be shipped from Jamestown to Europe.

Early on, the preparation of tobacco for shipping was quite simple. Dried tobacco leaves were

twisted and rolled to form a rope. This rope of tobacco was then wound into a large ball and

wrapped in canvas for shipment. Each bundle of tobacco might weigh as much as 100 pounds.

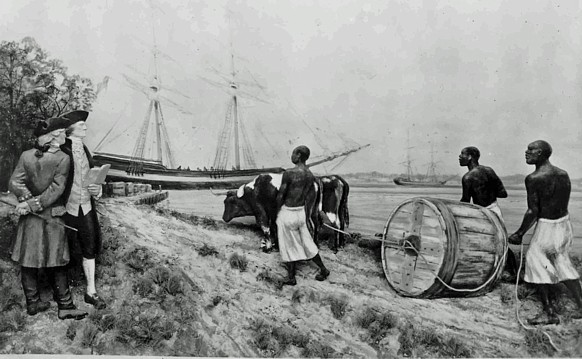

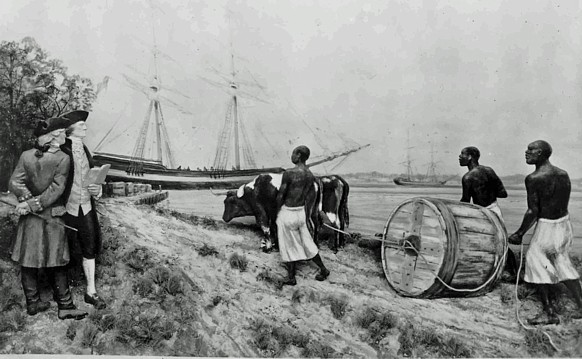

By 1640, though, tobacco production had spread across the colony and Virginia was exporting

nearly 2 million pounds of tobacco each year. With plantations springing up as far as 100 miles

from the coast, moving the product from inland plantations to shipping ports became an

increasing challenge. Planters addressed the issue by loading the tobacco into large wooden

barrels, called hogsheads, which could then be attached to draught animals and rolled from the

farm to the coast.

Early hogsheads were fabricated on the plantation and varied greatly in both size and shape.

It was not until 1708 that the Virginia Assembly passed an act to standardize the hogshead.

The new law established the standard height to be 48 inches with the diameter at the head to

be no more than 30 inches.

Tobacco Pressing

As important as the hogshead was for transporting tobacco over land, it offered even greater

benefits during the journey across the Atlantic. Because loose tobacco was relatively light, a

cargo ship’s “hold” could be filled to capacity and the ship would still be lightly loaded; making

the trip far less profitable. Using a hogshead, the tobacco could be packed tightly and the

containers could then be stacked to increase the amount of cargo delivered on each crossing.

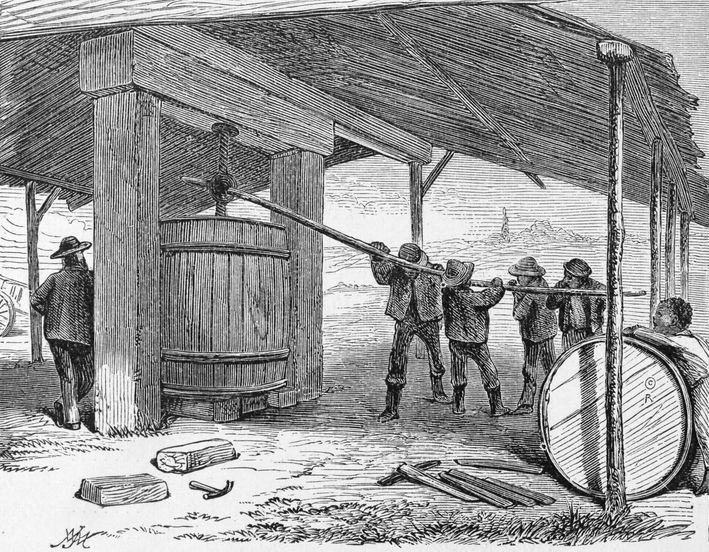

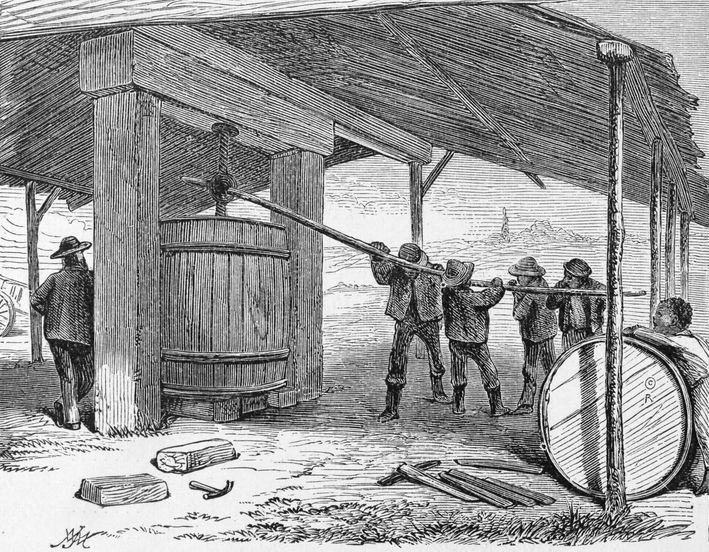

While a system of levers and weights were initially used to pack tobacco, enterprising planters

soon learned that a heavy screw could be used to compress the product into a hogshead. Layer

upon layer of tobacco were placed into the hogshead and then tightened down, before additional

leaves were added. By the time the process was complete, a single hogshead could hold 1000

pounds of tobacco. Using this technique, ships of the period could carry as much as 50,000

pounds of tobacco on a single journey – greatly increasing their profit margins.

Tobacco Inspection

With the continued expansion of tobacco production in America, by 1660 the English markets

were so glutted with the product that prices dropped to an all-time low of ½ cent per pound.

Faced with dramatic losses, the colonists began to mix leaves and sweepings from their floors

in with their tobacco, in an attempt to make up in sheer quantity what had been lost in low

prices. The benefit was short-lived as the export of ‘trash tobacco’ resulted in further depression

of market prices and colonial tobacco declined further in popularity. Quality issues continued

for more than fifty years as numerous, futile attempts were made to raise the standard of

exported tobacco.

It was not until the 18th century that an enforceable policy was affected. The Tobacco Inspection

Act of 1730 dictated that customs agents at every port were required to open each hogshead

before shipment and test two samples to ensure they were without defect. If a planter objected

to the inspection, the entire hogshead would be burned. The inspection policy was effective and

tobacco prices began to recover in later years.